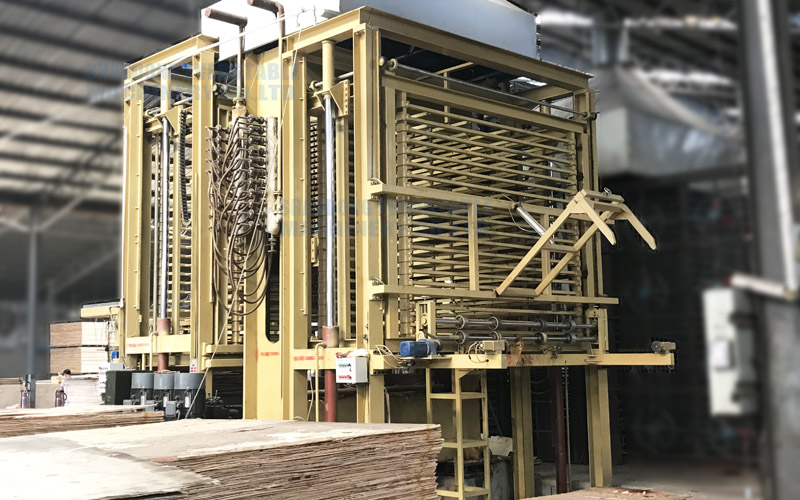

The hot press also called as the Laminating hot press is basic plywood working machine for plywood making line. Processing the assembled glued wood veneers into complete plywood sheet. Pressure support by the hydraulic oil cylinder and the heating can be thermal oil or steam boiler.

It can be used for various types of artificial board manufacturing, especially suitable for plywood production lines.

Parameter

- Work Table Size (mm): 2700x1370

- Pressure (TON): 800

- Daylight: 30 layers

- Hot Platen Size: 2700x1370x52mm

- Oil Cylinder (mm): Ø260x6

- Layer Distance (mm): 70

- Control Method: PLC smart control.

Features

Can be automatic or semi-auto loading and unloading the plywood.

Greatly improve the work efficiency and save labors.

High precision drilled hot platen with 52mm thickness

With double in and out heating recycle design, more smooth and uniform heat transfer.

Solid steel oil cylinder confirm good pressure distribution and no oil leakage.

Low noise hydraulic system. Make high efficiency pressure support, smooth closing and opening.

Simple and humanized operation .PLC smart control.

auto working and simple setting the lifting and pressing time and working pressure

Adopting quality fast closing hydraulic system with good synchronization, stable performance for quality furniture, construction plywood processing industry.

Shandong Everstable Machinery with a wealth experience in the veneer plywood & woodworking machine manufacturing area, with continuous improvement and after-sale supporting.Supply full set wood products making solutions, improving ,exporting and accessories supplying.

We insist on installing continuous relationship by supplying customer with good quality machinery and sincere after sale service. If you have any comments or production questions need help, please feel free to contact.