Products Description:

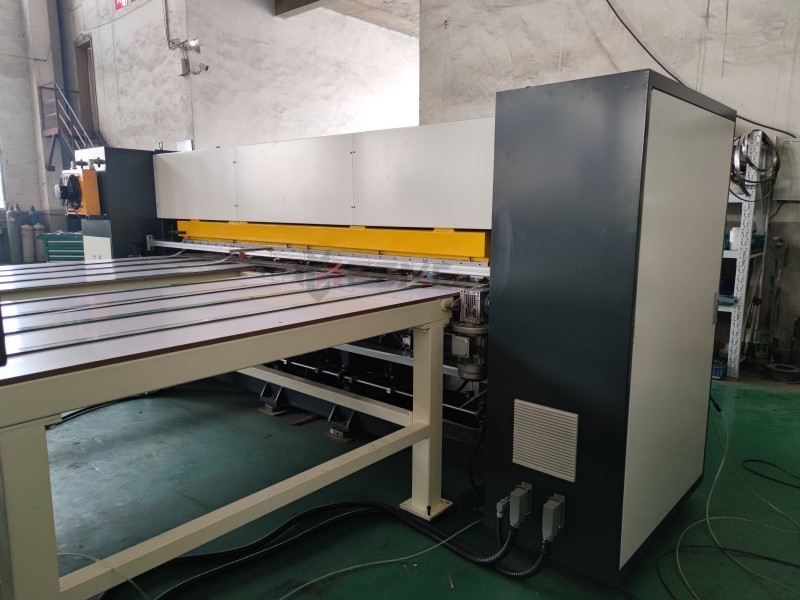

The Automatic Veneer Splicer Machine enables seamless veneer splicing with hydraulic-driven clippers that handle long veneer bundles efficiently.

Its crossfeed splicing surpasses longitudinal splicers in both speed and output, making it essential for high-volume production.

Key Features & Benefits

– High-Speed Production : Crossfeed system handles lengths up to 10 feet, significantly faster than conventional machines.

– Precision Pre-Glue and Cutting Systems : Dual-knife guillotines and pre-glue spreaders ensure precise edges for seamless joints.

– Infeed Guide System : Prevents misalignment, reducing initial stage errors.

– Advanced Sensor and Air Cleaning : Automatic dust removal keeps sensors clean every 30 minutes.

– Flexible Splicing Modes : Offers fixed-length or continuous splicing for varied production.

– Reliable Safety : European-standard light curtain provides robust operator safety.

Technical Parameters

| PARAMETERS/MODEL | ESPJ-2800 | ESPJ-3400 |

| Veneer Thickness | 0.3-2 mm | 0.3-2 mm |

| Splicing Veneer Length | 500-2800 | 500-3400 |

| Initial Veneer Width | 70-620 | 70-620 |

| Splicing Width | adjustable | adjustable |

| Oil Supply Capacity | 180L (46# wear-resistant hydraulic oil) | |

| Compressed Air | 6 Bar | 6 Bar |

| Power | 23.5 | 27.5 |

Our veneer cross feed splicer and splicing line are developed in partnership with top-tier woodworking machinery manufacturers in China, ensuring stringent quality control and high performance standards.

From design and development through material and component selection, production, installation, testing, and performance inspections, every stage follows strict manufacturing standards and procedures.

This attention to detail guarantees that the machinery installed at our customers’ facilities is stable, reliable, durable, and optimized for efficiency, resulting in the production of high-quality veneer sheets. We are committed to supporting your production needs with dedicated service and look forward to building a long-term, successful partnership.