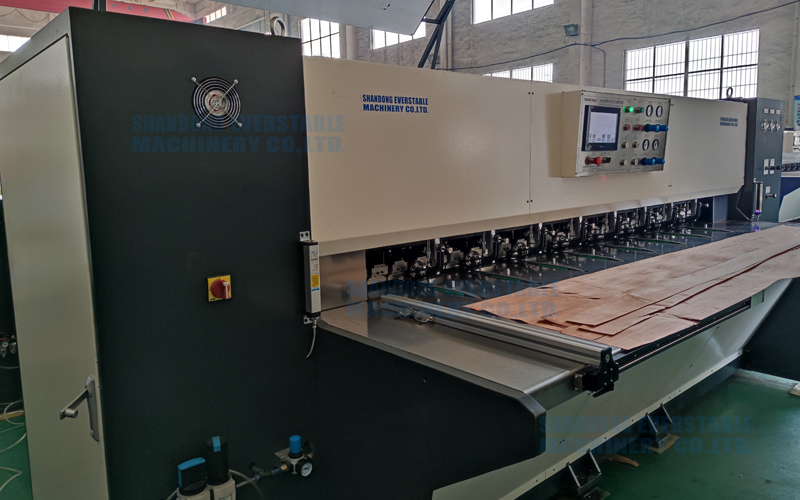

The veneer horizontal wireless jointing machine have pretty good performance for natrual face veneer of 0.3~2mm thickness.

Jointing the face veneers without using wire thread, only need small amount glue on the veneer sides, by the pressing and heating method firmly splicing the veneer together without gap, greately reduce the glue mark on the veneer surface, furniture face laminating industry.

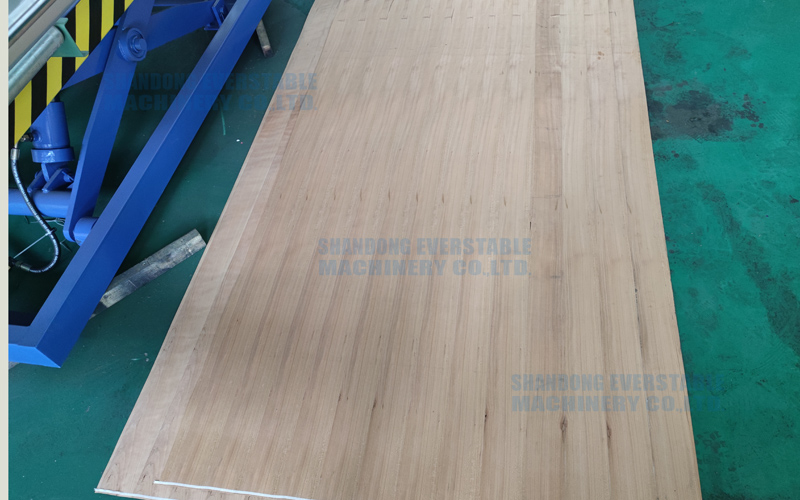

Smoothly splicing the sliced veneers or face veneer into needed size like 4x8ft. No need wires and have no residual.

Parameter

- Veneer thickness (mm): 0.3-3

- Max veneer length(mm): 400-2800

- Veneer cutting width(mm): 1300 or adjust

- Work efficiency (times/min): 15-30

- Power(kw): 24

- Feed and work direction: horizontal

Features

High-Speed Production: Capable of processing veneer sheets over 2 meters in length(4ft-10 ft can work), this crossfeed veneer splicer line operates at 6–7 times the speed of conventional longitudinal splicing machines, ideal for high-demand applications.

Equip Pre-Glue spreader and precision Cutting Systems: Equipped with dual-knife guillotines, the line ensures accurate straight-edge cutting, followed by a pre-gluing glue spreaderusing PVAc or urea glue for perfect joint preparation.

Flexible Controls: The intuitive PLC control panel allows operators to select either fixed dimensions,continuous composingor specified sheet counts, enabling easy customization for varying production needs.

Comprehensive Splicing Line: Integrated with Double-Sided Glue Applicatorfor precise adhesive coating and the short cycle hot pressing machine for for uniform veneer distribution, the line offers a complete, automated solution.

Our company will try best to offer you more convenient and satisfied veneer production experience.

One time cooperation, full term after sale service. Our engineer team will in first time reply you any problems and offer free suggestions and solutions.